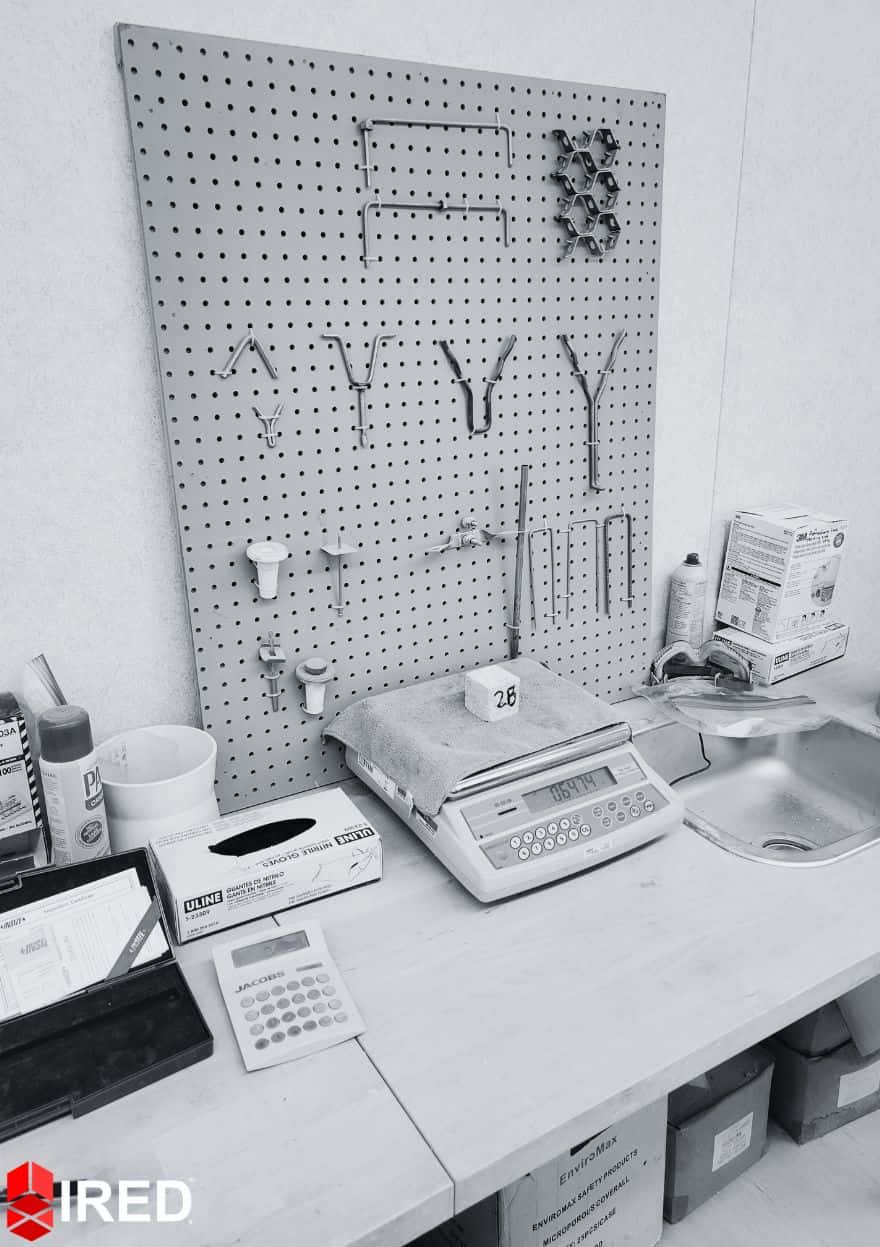

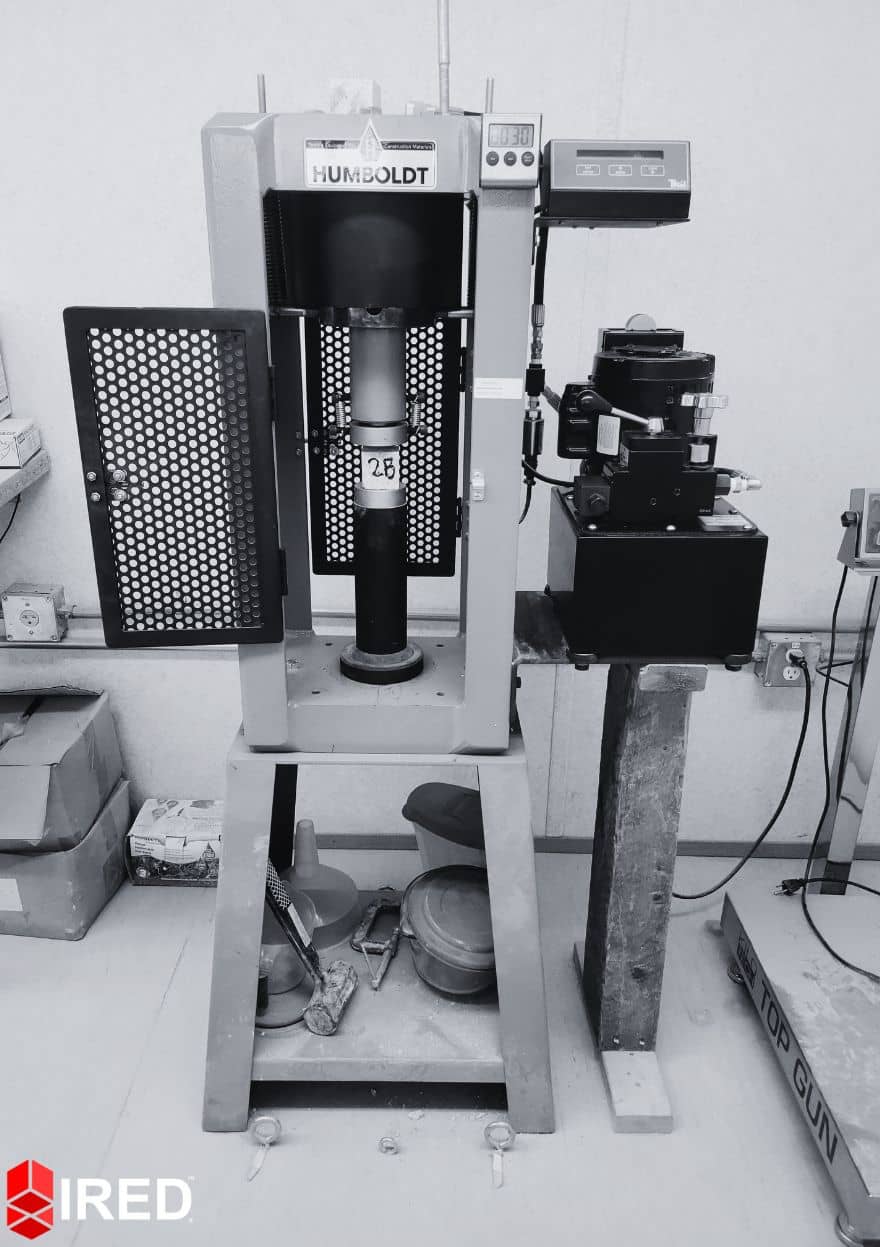

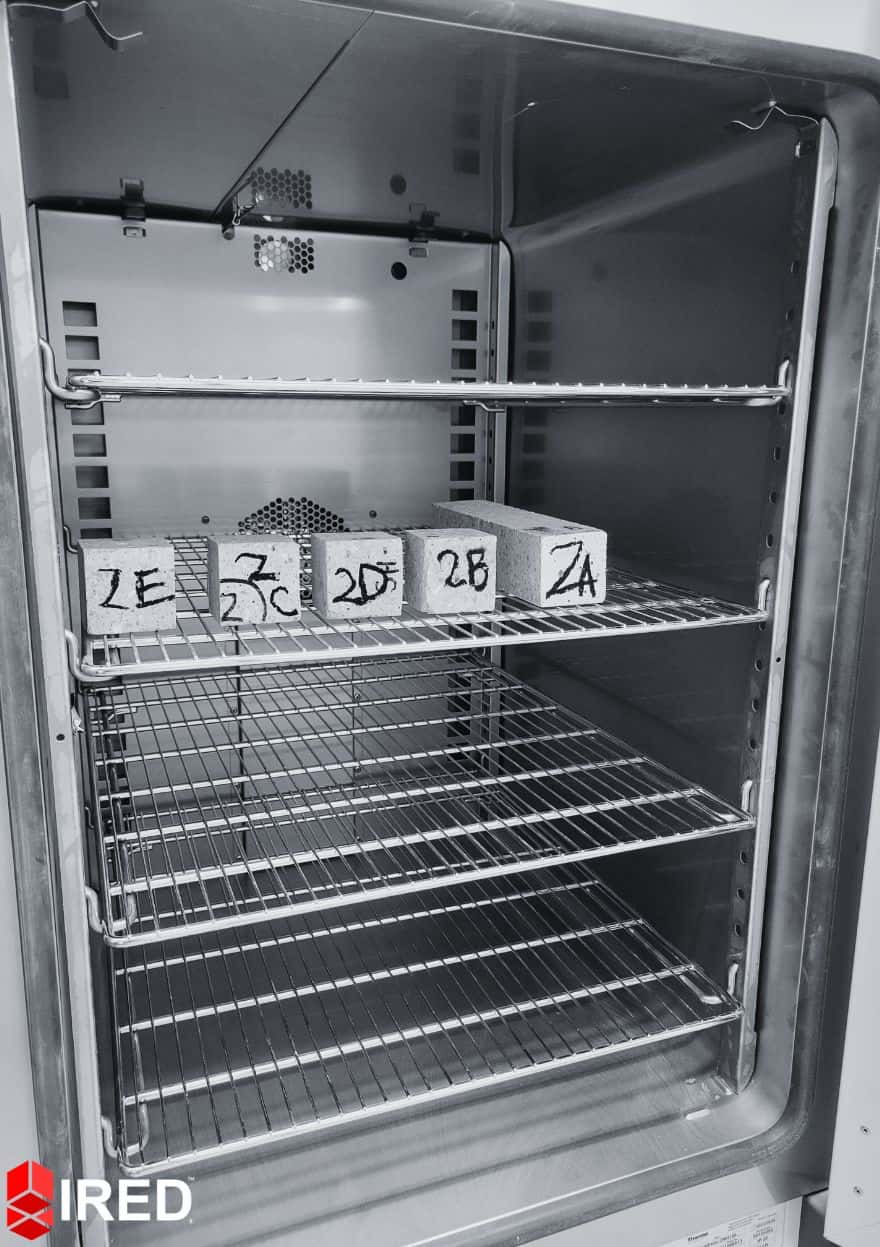

At IRED, we take pride in delivering a comprehensive range of refractory services tailored to meet your industry’s specific requirements. Drawing upon our expertise and unwavering commitment to quality, we offer solutions meticulously designed to enhance the longevity and efficiency of your materials.