Furnace and Reformer

Optimization & Redesign

IRED offers a wide range of services to optimize and redesign furnaces and reformers.

Our team of experts specializes in improving the efficiency and performance of these crucial refinery systems.

Furnace & Reformer Outlet Hydrogen Header redesign

By analyzing your existing system, we can identify areas for improvement and develop a redesigned header that maximizes the distribution of hydrogen throughout your process.

Furnace & Reformer Burner Tiles redesign

Burner tiles play a crucial role in the combustion process. Our team can assess the performance of your current tiles and develop a redesigned solution that enhances combustion efficiency and reduces emissions.

Checker wall (mixing wall), design and supply

This component plays a crucial role in optimizing the heat transfer within the furnace or reformer. Our team can design and supply a checker wall that enhances heat exchange and improves overall system performance.

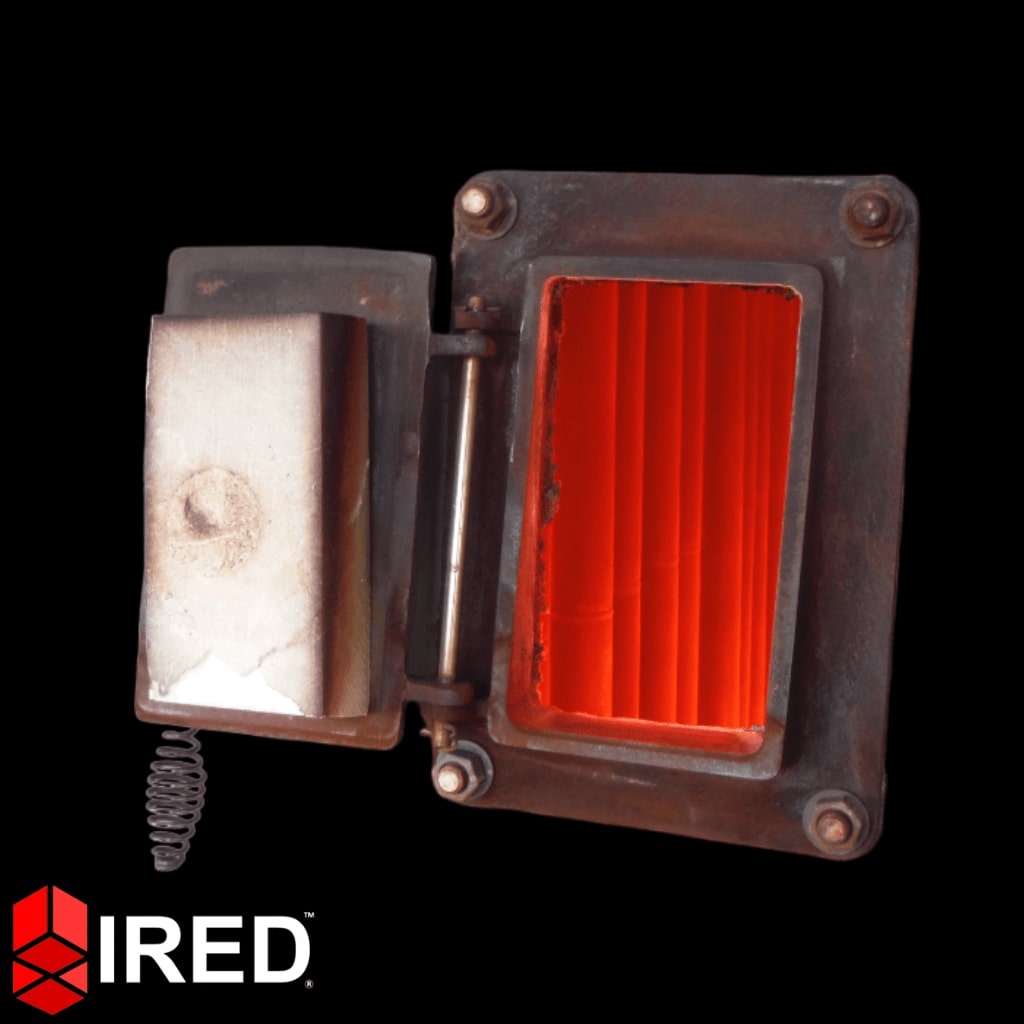

Furnace & Reformer Observation ports

We offer observation port redesign services to improve visibility and accessibility, allowing for better monitoring and inspection of your system. Our redesigns can include features such as improved lighting, better heat insulation, and easier maintenance access.

Furnace & Reformer Re-harping project execution

Over time, the harp or coil system inside a furnace or reformer can become worn or inefficient. We offer project execution services for re-harping, replacing old coils with new ones that are designed to improve heat transfer and combustion efficiency

Flue gas draft balancing

Imbalanced draft can lead to inefficient combustion and reduced system performance. Our team can analyze your flue gas draft system and make adjustments to ensure proper and balanced airflow, maximizing combustion efficiency.